100% Made in America

Impossibly Strong Hardened Bed

Built from Solid Dura-Bar Cast Iron

Meticulously Ground Surfaces

Brilliant Powder Coat Finish

Beautiful, Intuitive Modular Design

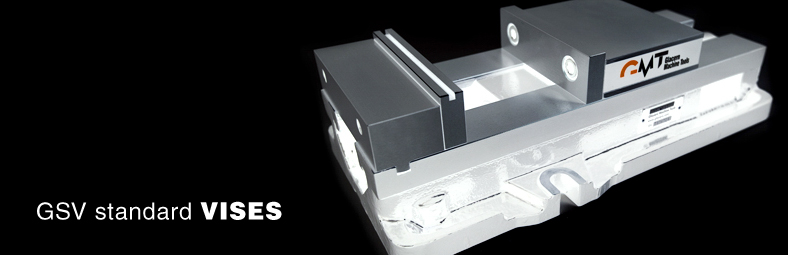

The 6.0-inch "GMV-EAGLE" Modular Vise

Bringing It Back,

American Values.

The Glacern Modular Vise is made entirely in the USA, from the metal we use right down to the smallest nut and bolt. Every manufacturing process including machining, grinding, plating, powder coating, heat treating, etc. is performed right here in Los Angeles, California. At Glacern, we're setting a new standard and boosting American manufacturing - helping pros - hobbyists - and tinkerers realize their goals. Uncle Sam has never been more proud.

"The Glacern Modular Vise reflects our values and beliefs, it is who we are and what we stand for." -The GMT Team

Accurate Material Hardening,

Precision Grinding.

Each Glacern Modular Vise is hardened on the bedways and jaw plates to HRC 50-60 and our Cage Locks™ are also hardened to ensure maximum durability, longevity, and toughness. Your vise will stick with you through many years of machining and is built to endure. We precision grind all of our vises so that they'll be flat, smooth, and exact. Purchasing multiple vises? Ask our metrology team about our complimentary bedmatching service. We'll match your vises to within +/-0.0005"

We use Continuous

Cast Iron Bar Stock

Every GMV Vise is manufactured from Dura-Bar, a ductile cast iron. It all begins with a water-cooled graphite die that is machined to form the shape of the bar. The die is mounted on a bar machine crucible, as the bar is pulled horizontally from the crucible, the head pressure feeds molten iron into the die, producing a fine-grained cast iron bar. This process enables the dense fine-grained microstructure to be free from shrinkage, gas holes and other inclusions, making it superior to carbon steel bar. The material also contains graphite in a pearlitic matrix which provides excellent wear resistance and vibration dampening.

Quality Materials, Built To Last

- Fully CNC machined vise body

- Solid Dura-Bar ductile cast iron construction

- Improved vibration dampening compared to steel, stainless, aluminum

- 2x the rigidity of aluminum

- Identical thermal coefficient as your machine

- Fully sealed, Niagara Lasalle e.t.d. 150® alloy steel lead screw

- No chip guards needed

- Hardened bed HRC 50-60

- Body fully stress relieved

- Chip evacuation port handles prevent swarf and debris buildup

- Powder coated body for increased corrosion resistance

- Over 10,000 lbs max clamping force

- Clamping repeatability < 0.0005"

- Anti-lift wedge design prevents workpiece lift

- Limited Lifetime Warranty

GMV Vise Dimensions Dimensions & Configurations

Double Station Mode

Single / Reversed Mode

| Dimension | GMV-EAGLE | ||

|---|---|---|---|

| A | Overall Length / Width | 20.00" x 6.00" | |

| B | Normal Jawplates / Center Jaw in Position 1 | Max FRONT Jaw Opening | 3.25" |

| C | Max REAR Jaw Opening | 3.25" | |

| B | Slim Jawplates / Center Jaw in Position 1 | Max FRONT Jaw Opening | 3.75" |

| C | Max REAR Jaw Opening | 3.75" | |

| D | Normal Jawplates / Single Station, Forward or Reversed | Max INBOARD Jaw Opening | 10.75" |

| E | Max OUTBOARD Jaw Opening | 20.00" | |

| D | Slim Jawplates / Single Station, Forward or Reversed | Max INBOARD Jaw Opening | 11.25" |

| E | Max OUTBOARD Jaw Opening | 20.00" | |

Specifications

| GMV-EAGLE | |

|---|---|

| Shipping Weight | 120 lb |

| Single Station Mode | Yes |

| Reversed Single Station Mode | Yes |

| Double Station Mode | Yes |

| Total Screw Travel | 8.25" |

| Maximum Clamping Force | 10,000 lb |

| Clamping Force to Screw Torque Ratio | 825 lbs per 10 lbs-ft |

| Clamping Repeatability | +/-0.0005" (measured in controlled environment with ground test block) |

| Center Jaw - Mounting Screw Size | 1/2"-13 x 2.00" UNC |

| Center Jaw - Mounting Screw Torque | 30 lbs-ft |

| Movable Jaw - Rear Set Screw Size | 1/2"-13 x 1.25" |

| Movable Jaw - Rear Set Screw Torque | 10 lbs-ft (for Single Station Mode ONLY) |

| Jawplate Screw Size | 1/2"-13 UNC |

| Jawplate Bolt Hole Pattern | 0.938" from base, 3.875" center to center |

| Jawplate Screw Torque | 20 lbs-ft |

| Friction Stop Set Screw | 1/2"-13 x 1.25" |

| Friction Stop Set Screw Torque | 10 lbs-ft (hand tight with T-wrench) |

| Friction Stop Travel Adjustment (for "Presetting") | 0.00" - 0.25" |